High Performance Overflow Valve for Air Dog & Fass Pump Users - OFV050HP

Increase

your horsepower and fuel pressure! At full power it will raise your

fuel pressure in the range of 37 to 45 psi. For use on moderately

modified Cummins trucks. Works much better than the old Bosch valve with

.168 inlet orifice. Now you can win at your competition event!

Do you experience low fuel pressure at wide open throttle (WOT) and

just accept it as normal? Have you ever thought that low fuel pressure

gives your competitor an edge?

Anthony Reames, the technical manager at Air Dog, asked us to solve

the low fuel pressure problem with the Bosch P pump. Cummins owners

report that the fuel pressure drops to as low as 16 PSI during full

throttle runs. We jumped on this technical request because we thrive on a

challenge. Solving problems is what Tork Teknology is all about.

The first thing we did is throw all assumptions out the window. We

found that in most cases, they can be very misleading. Our slogan, that

we live by, is "one good test is equal to a thousand expert opinions".

This is how we attack a problem.

After installing an Air Dog II DF165 on our '98 Dodge Cummins test

truck, we routed the 1/2" feed line to an accurate flow meter and ran

all the return fuel through an additional flow meter. The fuel pressure

was monitored by a glycerine filled pressure gauge. The results (shown

left) align exactly with proven hydraulic formulas. Fluid will flow a

specific volume through an orifice at a specified pressure and specific

gravity. Simply put, a fluid will flow more volume (gpm) as the pressure

increases through the same size orifice. Put another way, reduce the

orifice diameter, and the GPM flow will drop.

You may have asked yourself why Air Dog and FASS equipped Dodge

Cummins trucks will show good fuel pressure at idle and cruise, but the

pressure drops at full throttle, to as low as 16 PSI. Take a look at the

photo above. The flow meter indicates diesel fuel flow of 1.09 GPM.

This is the volume of fuel flowing thru the inlet orifice at the base of

the overflow valve. (see photo right) Actually, it translates into 1.14

GPM (multiply number by 1.0495 correction factor) flowing into and out

of the P7100 pump. That is the volume of fuel flowing back to the

tank through the Cummins overflow valve. Yes, we tested both the Bosch

and Tork Tek overflow valves. If you are using one of the old Bosch

valves with the .168 inlet orifice, your fuel pressure will never allow

you to win ANY competition event becuase of very low fuel pressure.

ELECTRIC PUMPS DO NOT WORK WELL WITH THE P7100

UNTIL NOW

I'm not saying that the Air Dog and FASS are not good pumps. Both are

quality pumps. The problem is the orifice leakage is too large and

bypasses too much fuel to tank. This leakage produces low fuel pressure

at WOT.

We now know that the inlet orifice on a standard Bosch overflow valve

will flow 1.14 GPM back to tank. This is how it lowers your fuel

pressure and kills your Cummins diesel performance! If you run an

AirDog 100 GPH (gallons per hour) pump, you are pumping 1.66 GPM. (100

GPH divided by 60 minutes/hour = 1.66 GPM) You are losing 69% of your

pump volume thru the overflow valve. That's almost 75% of the fuel doing

no work at all! Let's do the numbers for the Air Dog II DF165 which is

rated at 2.75 GPM. If you lose 1.14 GPM to tank, 41% of your pumps

capacity is LOST. Let's suppose you use the AirDog II DF200 which flows

3.33 GPM. 34% of the pumps capacity is doing nothing for your

performance 12V Cummins.

It's easy to see why performance P pump users are showing low fuel

pressure at WOT. Too much diesel fuel is pumped through the Bosch

overflow valve and back to tank. This translates into lower HP and

torque performance numbers with your Cummins 12V. It could make the

difference between winning or going home defeated.

Another problem that we uncovered was at a very specific pressure,

the fuel flow through the overflow valve can be dead headed. This can be

dangerous as the P pump needs fuel flow to help keep it cool. If you

set the AirDog pressure regulator to slightly less than the OFV setting,

fuel flow and pump cooling STOP. Also if you adjust the OFV by

adjusting the shims, stretching the spring or adjust the Tork Tek

overflow valve, the same problem can exist. The solution had to cure low

fuel pressure and eliminate any possibility of stopping fuel flow thru

the valve.

WHAT ABOUT INJECTION PUMP COOLING?

We know from testing the Cummins 5.9 fuel system, with the stock lift

pump, that fuel flow is .59 GPM (max) at 2200 RPM. The engineers at

Bosch spent a lot of R & D time to make sure the P pump stayed cool

at the fuel flow the lift pump delivered. The Bosch P7100 injection pump

will run without problems for 300 to 500,000 miles or more! There are

commercial trucks that have seen 1,000,000 miles with the P pump and the

Cummins lift pump.

The smallest of the four valves is the OFV070HP. This valve is for

super modified, race only trucks. The 070HP orifice will flow .565 GPM

at 45 PSI. So, even with the smallest of the valves, you will still be

within 4% of the cooling capacity of a stock system.

THE NEW HP OVERLOW VALVE - A TESTED SOLUTION

How did we test for a solution? We machined 12 prototype overflow

valves with replaceable orifices, similar to Holley carb jets. The beta

testers could now replace the jet with a smaller one to the point where

the fuel pressure was aceptable at WOT. In other words, the fuel

pressure remained constant from idle to full throttle. Each jet change

and fuel pressure reading was documented on a chart. In addition, I made

the same tests on our '98 Dodge Cummins 12V.

It became clear after the testing was complete, which sizes cured the

problem. Each size created a fuel pressure range at WOT. We also

discovered that a very small change in orifice size will make a dramatic

change in fuel pressure and fuel flow.

FUEL PRESSURE MAKES HORSE POWER

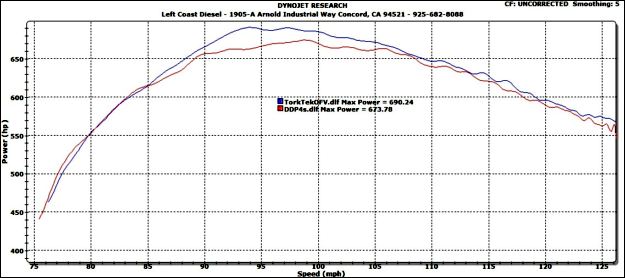

To illustrate how fuel pressure can affect Cummins diesel horse power

and torque, one beta tester asked his brother to try the prototype

valve on a dyno. The owner of Left Coast Diesel made a run with a

standard Cummins OFV and then installed the prototype Tork Tek HP valve.

The first thing he noticed was consistent fuel pressure across the RPM

band. No other changes were made to the engine. He achieved a 27HP

increase for 3 minutes worth of work. His power increased from 663HP to

690HP at 93 MPH. That 27 peak HP increase can be the difference

between winning and losing.

What fuel pressure should you be running? Here is a general

rule to determine the fuel pressure you should be at. Multiply the

governor spring rpm (in thousands) times 10. In other words, you want 10

PSI of fuel pressure per 1000 RPM of govenor speed. If you installed a

3K govenor kit, you need a minimum of 30 PSI at full power. A 4K kit requires 40 PSI at WOT. 5K equals 50 PSI. Remember, this is at full power, not idle or cruise.

Fuel pressure will be in the 43 to 50 PSI range if you add the 40 PSI

spring. The standard spring will limit the fuel pressure you can reach.

If you are using the original Air Dog pump, it is factory set at 30

PSI. If you want higher fuel pressure, you will have to install a 40 PSI

spring. The AirDog I and II use different springs to achieve higher

fuel pressure. They are not interchangeable. Please note that you will

not achieve higher fuel pressure by swapping out the spring. You have to

fix the leak first.

Do not use the HP valve on a stock fuel system! This valve will raise

pressure spikes to the point that the stock fuel filter canister will

blow a seal. The valve is intended for Cummins P7100 trucks using a

FASS, Air Dog or high volume, performance fuel pump only.